While ceramic tiles are perhaps not the first products you would expect to see with an environmental rating, the impact of manufacturing zircon-containing tiles has now been quantified with the publication of the first ever cradle-to gate Life Cycle Assessment (LCA) of zircon sand. The LCA clearly demonstrated that zircon has an overall low environmental impact. In addition, a comparison study of LCA data showed a significantly lower environmental impact for zircon when compared to calcined alumina, an alternative opacifier (whitener) in ceramic tiles. Importantly, this study used industry primary data, along with the latest lifecycle engineering and impact assessment methodologies, with each step peer-reviewed by a panel of three independent LCA experts to ensure conformity to ISO 14040/44 standards.

As a natural mineral, zirconium silicate (zircon), when milled into a superfine powder, has been used in the manufacture of high quality ceramic tiles for decades: in porcelain tile bodies, engobes and glazes.

The superior technical properties of zircon are well known to the ceramics industry and makes it the material of choice: higher opacity (whiteness) particularly for brilliant white, glossy tiles; better resistance to surface abrasion and chemical attack; lower refractoriness and other benefits during the tile manufacturing process. Now, in addition to these technical advantages, the environmental credentials of zircon have been quantified for the first time by using a LCA study.

The study report, commissioned by the Zircon Industry Association (ZIA) and entitled ‘Life Cycle Assessment of Zircon Sand Production Applied to Ceramic Tiles’, examined the environmental impacts associated with the production of 1kg of zircon sand. The results showed that the overall environmental impact relates largely to electricity consumption associated with the initial mining (extraction, separation and drying) of zircon sand, much like the mining of other minerals. The downstream processing (dry milling) of zircon was shown to have a comparatively much lover environmental impact.

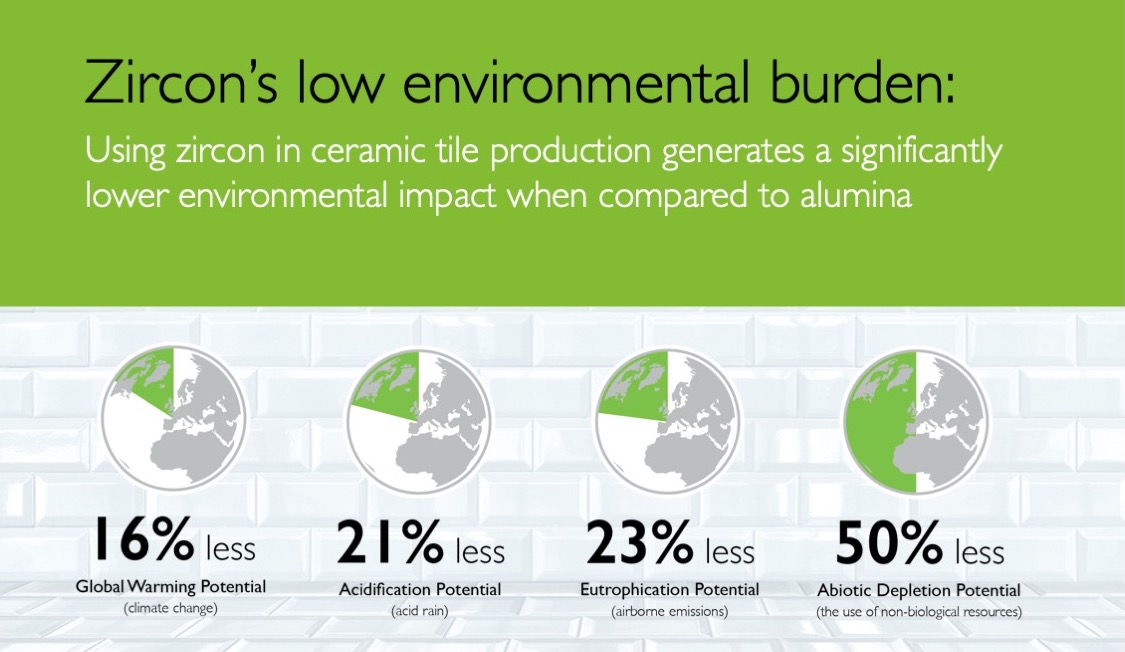

In a second phase, the study went on to compare the environmental impact of using zircon as an opacifier in 1kg of porcelain ceramic stoneware tile mix, to that of using alumina. Results showed that using zircon as the opacifier generated significantly lower overall environmental impacts when compared to alumina in ceramic tile manufacturing. This was shown to be valid over a range of key environmental indicators selected according to international standards.

The Global Warming Potential (used to quantify climate change) was 16% lower for zircon than with alumina, while the Acidification Potential (linked to acid rain) was 21% lower and the Eutrophication Potential (associated with airborne emissions) was 23% lower with zircon.

Scenario analysis demonstrated that these conclusions were valid even when allowing for variability and making the ‘worst-case’ assumptions for the zircon-containing tile mix and the ‘best-case’ assumptions for alumina. The Abiotic Depletion Potential (a measure of the depletion of natural resources) was approximately 50% less for zircon-containing tile mixes.

Three other key indicators (Abiotic Depletion Potential (fossil), Photochemical Ozone Creation Potential, and Primary Energy Demand) were all found to be some 20% lower when using zircon-containing tile mixes. Only one indicator – Ozone Layer Depletion Potential – was similar for both zircon and alumina.

As an environmentally responsible industry, it is important that the zircon supply chain is able to quantify the overall environmental impact of mining and processing zircon sand. A reliable benchmark for zircon sand production is now available, which confirms that the majority of its, albeit low, impact is related to upstream electricity consumption.

In addition to the superior technical qualities of zircon compared to alternatives, the LCA shows that manufacturers can use zircon in ceramic tile production safe in the knowledge that its overall environmental impact is low. Moreover, the comparison study demonstrates that tile users - such as architects, interior designers, building contractors and individual consumers - can actively reduce their own environmental footprint by specifying zircon-containing ceramic tiles.