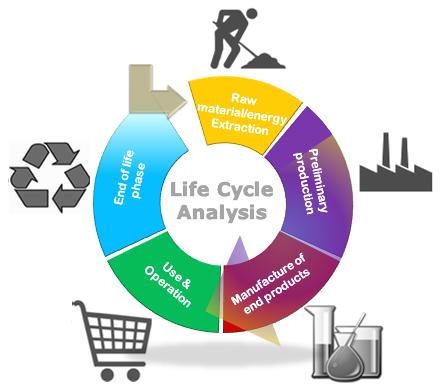

The overall aim of an LCA is to assess the impact of energy and materials used and releases to the environment, and to identify and evaluate opportunities to effect environmental improvements.

There are four key components of an LCA:

The Zircon Industry Association completed the first ever global LCA for the use of zircon in the manufacture of ceramic tiles. The report, entitled ‘Life Cycle Assessment of Zircon Sand Production Applied to Ceramic Tiles’, examines the environmental impacts associated with the production of 1kg of zircon sand. This was a ‘cradle-to-gate’ study, covering all production steps from mining (including mineral separation and milling), through to delivery to the ceramic tile manufacturer’s ‘gate’.

The ISO-standard project, which was peer-reviewed at each step by a panel of three independent experts, also demonstrates a significantly lower environmental impact for zircon over a range of environmental indicators compared to alumina when used as an opacifier in ceramic tiles.

The LCA confirms that zircon sand manufacture has a relatively low overall environmental impact, overwhelmingly associated with local electricity consumption linked to upstream mining processes (extraction, separation and drying), much like the mining of other minerals.

The study went on to compare the environmental impacts of using zircon as an opacifier (whitener) in 1kg of porcelain ceramic stoneware tile mix compared with alumina, the main alternative product. It found that tile production using zircon generates significantly lower overall environmental impacts over a range of environmental indicators.

This study compares the use of opacifier (whitener) materials zircon sand and alumina applied in ceramic tiles production. The life cycle assessment study, commissioned by ZIA, provides a comparison using a cradle-to-gate life cycle assessment (LCA) approach. Using primary data from industry, it compares the environmental impacts of either using zircon or alumina in tile body mixtures to produce tiles with a high degree of whiteness.

This ISO-compliant study was reviewed by an independent, expert panel and presents the first Life-Cycle Assessment comparison between zircon and alumina, using primary data from industry.

This work follows the first ZIA study ‘Life Cycle Assessment of Zircon Sand Production Applied to Ceramic Tiles’ published in 2017.

We aim to support the zircon market by responding to industry issues, by developing new applications for zircon and by enhancing existing applications for zircon wherever possible.