While there are a number of major industrial zirconia and zirconium chemical applications in the nuclear industry, or in gas purification and ammunitions, there are many everyday applications that make use of zirconia’s superior properties. Whether it is in antiperspirant deodorants, or being used as a coating to add strength and water resistance to paper, or as a brilliant gemstone, zirconia impacts everyday life in many ways.

More detail on all of these chemical applications can be found in the Zircon Technical Handbook .

Below is a brief summary of the many different chemical applications that make use of zirconia’s and zirconium's properties:

Cubic zirconia has become a popular gemstone due to its optically clear single crystals and its high refractive index. It also maintains its colour and brilliance. It is classified as a soft to semi-hard gemstone and is available in a colourless form or in different colours, including red, yellow, orange, amber, brown, pink, violet, blue or green. Colour is dependent on the dopants used during its production.

Zirconia can exist in three phases: cubic, tetragonal and monoclinic. Naturally occurring pure zirconia (Baddeleyite) is a monoclinic mineral in which the cubic phase is only stable at high temperatures. In order to stabilise the cubic phase at low temperatures, zirconia is commonly mixed with oxides. Typical market grade cubic zirconia contains 87.5% zirconia and 12.5% yttrium oxide. This improves the thermo-mechanical properties of cubic zirconia and stabilises it at low temperatures, giving it high strength, toughness and thermal shock resistance. Important properties include:

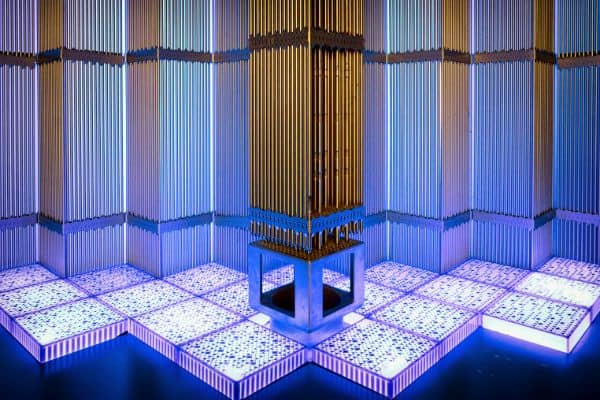

Zirconium alloys are widely used as structural components in the nuclear industry including in pressure tubes, fuel channels, guide tubes, grid spacers, for fuel cladding, for fuel containers or even as the core structural materials of water-cooled nuclear reactors.

It is alloyed with other materials, such as tin, to improve mechanical and thermal properties and offer excellent corrosion and irradiation creep resistance as well as low neutron-absorption. These are critical to increase the efficiency of the nuclear reactor given lower neutron absorption results in greater efficiency. These materials have to be able to withstand high temperatures and reactive conditions such as irradiation, oxidation and hydrogen pick-up.

Zirconium metal employed in zirconium alloys is obtained from zircon by carbo-chlorination process at 2000°C, following the removal of hafnium and its subsequent reduction with metallic magnesium.

Titanium dioxide is widely used as a pigment in the global paints industry due to its optical properties, non-toxicity and chemical inertness. However, it has a high photo-catalytic activity under ultraviolet irradiation which leads to the decomposition of paint films. Zirconium coatings are used on TiO2 particles to improve their photo-stability and shield the photo-catalytic effect.

Titanium dioxide’s strong oxidising properties has also seen it successfully employed as a photocatalyst that can oxidise and decompose harmful organic contaminants such as bacteria, viruses, volatile organic compounds and algae spores. This material has been commercialised as a spray that can be applied as a coating on a wide range of materials, particularly on walls and other interior surfaces in buildings and houses. Photocatalysts, such as titanium dioxide, need to absorb light to be able to oxidise organic compounds. Zirconium has been used as a dopant to increase the photocatalytic activity of TiO2 by increasing the efficiency of the process and allowing the absorption of visible light. Zirconium doped TiO2 coatings have become more effective at triggering the oxidation reactions necessary to improve air quality in closed building spaces.

Aluminium zirconium complexes are commonly used in antiperspirants, where they help to dissolve sweat and stop it flowing to the surface of the skin. They are mostly contained in sticks, gels and other solid products.

According to the European Commission Scientific Committee on cosmetics and non-food products and the US Food and Drug Administration, zirconium and zirconium compounds should not be used in cosmetic products with the exception of zirconium lakes, salts and pigments of colouring agents and a number of aluminium zirconium complexes. More information on the particular aluminium zirconium complexes can be found in the Zircon Technical Handbook.

Zirconium chemicals are widely used in the paper industry as coatings that add strength and water resistance to paper.

Ammonium zirconium carbonate (AZC) is the most frequently used compound for paper applications. The ability of zirconium compounds to replace formaldehyde, which the paper industry wishes to remove, is well exploited in the paper industry.

Zirconium chemicals are employed as additives in paints and inks to promote adhesion to the substrate and increase their resistance to heat, scrubbing, water and solvents. Zirconium compounds have also been used as driers in solvent-based paint, as well as thrixotropes in water-based chemicals.

As a paint drier, zirconium has been employed as a substitute for lead, which has been banned across most of the world due to it toxicity. In inkjet coatings, zirconium compounds are used to improve the water-fastness of the coating and print quality. They also promote better adhesion to plastic and metal substrates.

During the process of catalysis, a catalyst augments the rate of a chemical reaction without being consumed in the reaction. In addition to accelerating a reaction, a catalyst can also make the reaction behave in a more selective manner. Zirconium compounds are used as catalysts in a large number of chemical processes. The main applications include:

Zirconium powder is highly flammable and can be easily ignited. This property has lead to its use in ignition charges, ignition mechanisms for automotive airbag inflators, pyrotechnics and squibs and military applications such as incendiary charges.

.jpg)

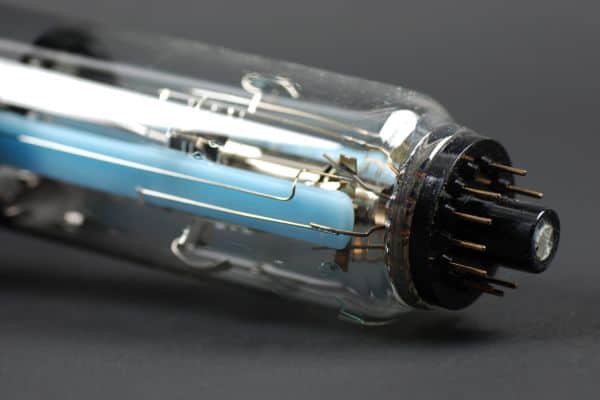

Getters are materials that can be placed inside a vacuum system to remove small traces of gas from the system through chemical combination or adsorption. Zirconium is a highly effective absorbent because its surface bonds with almost any gas species.

Zircon and its derivatives have a vast array of applications. The largest market for zircon is the ceramics industry. Approximately 54% of zircon that is produced is used in finely ground form in the ceramics industry. 14% goes is used by the foundry industry, and approximately 11 - 14% is used in refractory applications.

A growing portion of the zircon mined worldwide is used for the extraction of the metals zirconium and hafnium or their further processing to produce zirconium chemicals. There is a considerable number of further uses and it is clear from emerging research and development that zircon will continue to play an even greater role in the technological advances of the modern era.