For the past few decades, architects have battled to combat the urban heat island phenomenon in many cities. The materials on which these metropolises are built, such as concrete, steel and asphalt, absorb the sun’s heat and store it in large thermal masses. This, as well as the waste heat generated by energy usage, ensures the temperature in cities can be significantly higher than nearby rural areas. The result is that many cities across the globe are uncomfortably warm in the summer months and, as everyone reaches for the air conditioning buttons, energy consumption rises and so too do CO2 emissions into the atmosphere.

Architects, specifiers, and their clients strive to mitigate this heating effect through design and the materials they employ. Over the years, one of the solutions to address urban heating is to design building envelops that utilise ‘cool materials’ with high reflective properties. The so-called ‘cool roof’ concept. It is widely proven that using roofing materials with high solar reflectance and high thermal emissivity can decrease the indoor temperature of buildings by about 2.5°C, thus reducing a building’s summer cooling energy requirements, for example, by as much as 43% in Florida and 30% in Rome. This offers significant cost savings in terms of energy, but also a considerable reduction in CO2 emissions.

Spray paints and sheaths, waterproof membranes, poly bitumens, corrugated sheets and ceramic tiles are all high-reflectance materials used by building designers for cooling roof structures. The most effective paints are white, with high solar reflectance and excellent thermal emissivity. However, in recent years the focus has turned to the long-term performance of these materials. Tests in the outdoor environment show that, due to exposure to atmospheric agents and fouling, the solar reflectance of roofs using bituminous membrane coated with cool acrylic paint is almost halved within two years. Therefore, cool coatings have required periodic washing, maintenance, or restoration treatments, which are all costly and time-consuming. Ceramic tiles have far greater overall durability and resistance to atmospheric damage and, with increased solar reflectance, could offer a lower maintenance solution.

Ceramic tiles undergo various quality tests, including freeze thaw cycles (ISO 10545-10), thermal shock (ISO 10545-9) and solidarity of colours to light (DIN 51094), during their certification. These tests show that porcelain stoneware tiles do not undergo colourimetric variations or solar reflectance reduction due to UV radiation or hygrothermal shocks. It has now been shown that the addition of solar reflectance boosting zircon to glazed ceramic tiles substantially improves the potential of ceramics as a low maintenance cool roof and cool façade material, which is more durable in terms of resistance to deterioration and wear. Ceramic surface glazes can also be designed with a finish that increases tiles’ cleaning performance, substantially reducing overall maintenance costs.

Laumans use zircon-containing glazes in many of their products. They apply the glaze by showering the tiles, producing a 40% greater thickness than spraying or spinning. When fired, it results in an extremely hard and protective surface enabling a 30-year tile guarantee. Photo credit: © Laumans

Kiln cars and entry to the tunnel kiln. Photo credit: © Laumans

The recent study looked at the effects of adding zircon to ceramic glazes of various colours including black, brown, blue, green, and yellow. Carried out both on a laboratory scale and by field trials, zircon was added to 36 tile samples both as an opacifier directly into the glaze formulation (up to 10 wt%) and as frit component (up to 6.6 wt%). A frit is a ceramic material that has been melted, quenched and granulated. The solar reflective index (SRI) was calculated for each sample. The colorimetric coordinates were also determined to evaluate any colour variation due to the presence of zircon. The thermal performance of the samples was automatically monitored every 30 minutes in an outdoor environment during the hot Italian summer months (June to September 2018).

Results of tests carried out on the samples of glazed ceramic tiles show that, in general, an addition of zircon increases the solar reflectance index (SRI) of the surface glaze, the effect being more pronounced when zircon is added as an opacifier. Also, as the zircon content in the glaze increases, the SRI value increases linearly for all colours in this study. The increase in SRI is greater in percentage terms when zircon is used as an opacifier, and greater in absolute terms when zircon is used as a frit. The SRI percentage increase is more pronounced for darker colours (black, brown, and blue) when zircon is used as an opacifier. The black glaze saw an SRI increase of 90% when 10 wt% zircon was added, while brown saw a 43% increase, blue a 45% increase, green a 33% increase, yellow a 23% increase and the white tile saw a 21% increase in SRI.

Monitoring of each tile’s surface temperature when exposed outdoors to solar radiation confirmed that the measured higher values of brightness and solar reflectance parameters of the surface glaze are entirely due to the addition of zircon. In these field trials, a clear decrease in surface temperatures (i.e. a cooling effect) was observed for glazes where zircon was used as a frit component. The frit composition containing 3.3% zircon was observed to be the most effective in cooling.

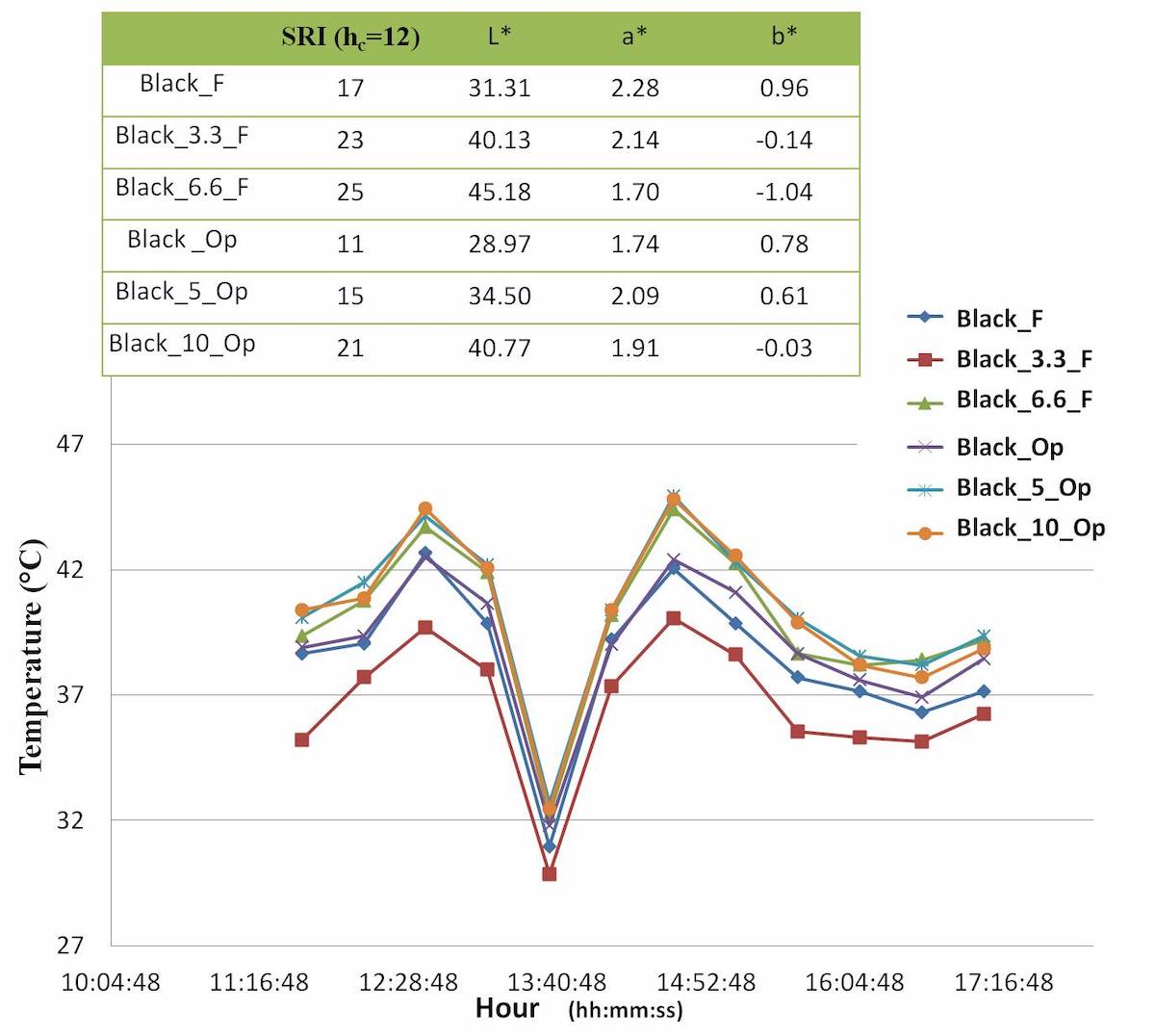

Fig. 1 below shows the monitoring of the surface temperature of black glazed samples. The graph shows that the black tile sample with 3.3% zircon in the frit when exposed to solar radiation maintains lower surface temperatures of up to 5°C when compared to the other black glazed samples.

Figure 1: SRI values, colorimetric coordinates, and variation curves of the surface temperatures of black glazes containing zircon as opacifier (Op) or as frit (F), during monitoring on a sunny day. For hourly intervals considered in the figure, the ambient temperature varied from 27 to 32 ° C.

The study concluded that zircon addition increases the cooling effect in the composition of glazes for ceramic tiles. These zircon-containing tiles, if used as a building envelope, could improve the thermal comfort in the building by reducing energy demands and, compared to alternatives on the market, such as paints, are able to reduce maintenance costs thanks to their high resistance to wear, dirt and stains.

As the drive for sustainable solutions in our modern world intensifies, consumers are more aware than ever before of the impact of their lifestyle choices. While we now know that zircon-containing roof tiles can offer a sustainable solution as a ‘cool material’ for building envelopes, their environmental credentials do not end there.

A recent Life Cycle Assessment (LCA) for zircon sand concluded that zircon has an overall low environmental impact and the impact is lower than alumina - an alternative to zircon as an opacifier (or whitener) in ceramic tiles.

Minimising the environmental impact of how we live is a global issue. Many tile producers already offer beautiful glazed, zircon-containing roof and façade tiles which are used to create visually stunning, memorable buildings that have significantly less energy demands and offer increased thermal comfort to those who use them. This study shows that by actively choosing zircon-containing glazed tiles for a building’s envelope, architects, designers, and their clients can significantly reduce the overall environmental impact of the building, while minimising maintenance requirements over time. It is clear that by adjusting the composition of their glazes, tile producers can play an important role in the sustainable development of our world.